Project Description

CLIENT | Leading Oil Major

VESSEL | Oil Tanker

DATE | Nov 18

LOCATION | Singapore

Overview

Approached by the Client to inspect its vessel’s engine as issues and concerns had arisen over its performance.

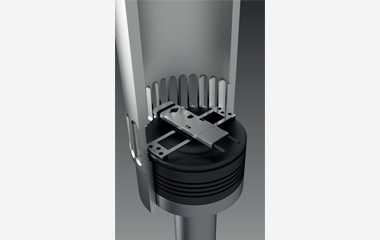

Scavenge Space Inspection showed no major signs of failure; hence, CTS went on board to carry out an in-situ liner inspection. We utilise a machine that can be easily deployed from the liner scavenger ports and upon inspection and analysing the data,

CTS provides the probable causes of failure and the possible solutions.

What the Inspection provides:

1. Liner diameters, wear rates, ovality data.

2. Liner issues such as scuffing, clover leafing, high corrosive wear.

The main concern for tankers in Singapore/worldwide is:

1. Immobilisation of the main engine.

2. Very short and uncertain port stay.

CTS engages a technology which allows:

1. No immobilisation of the Main Engine. (It does not require any engine mounting to be removed).

2. A very quick, yet sophisticated method of liner inspection and analysis (taking only 20 minutes per liner).

Scope of Works

Implementation

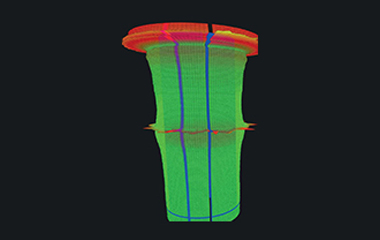

The machine intelligently self-calibrates and records the required data. Working on the principle of measurement by laser it subsequently provides a 3D liner wear analysis.

The data is then decrypted to give the user access to the following records:

1. Liner maximum dia (machine scans around 200 readings of the liner at various points while continuously rotating).

2. It provides the average wear rate, determining the remaining life hours of the liner.

3. The data interprets the ovality curves of the liner.

4. The tabulated data is used to graph the wear profile along the full depth of the liner.

5. The data is interpreted to point out concerns/issues of cloverleafing, adhesive wear and corrosive wear.

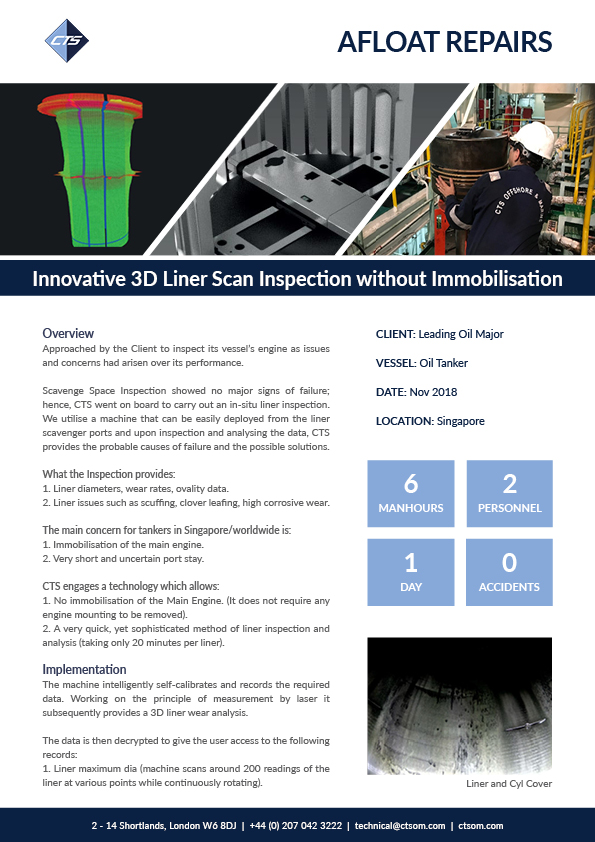

CTS also uses a camera that can take pictures of the liner and cylinder head. These photos can be co related to the graphical data to show any issues/failures.

In this case, the liner of one of the 6 units was completely scuffed though the other 5 liners were in good condition.

The data and photos proved that the liner in its entirety was scuffed. Possible causes are the failure of the alpha lubricator for that unit.

Project Gallery

Result

The results of the inspection and analysis were thorough and successfully evidenced so that the advice we offered to the Client, was well founded and quantifiable. We advised the Client to renew the liner at the earliest opportunity to prevent failure of rings.

Due to over delivering and surpassing expectations, CTS is pleased to share that the client has contracted us for work on further vessels this coming year.

Client Feedback

The Fleet Manager was very pleased with the results.

He was assured by the data provided, and his doubt was confirmed that the liner had failed and should be renewed.

He was impressed by the machine methodology of deployment and data interpretation.