SPS Overlay

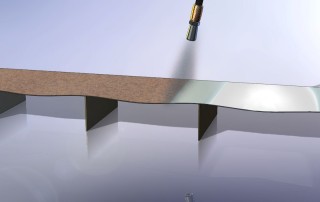

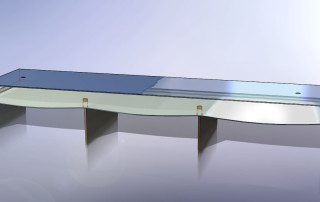

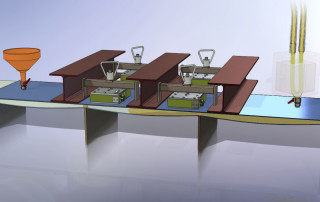

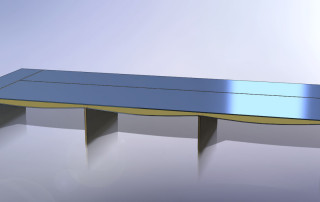

Overlay is the process by which original structure are reinstated with SPS. The existing structure is retained and reinforced with a new steel layer and polyurethane core resulting in a strong, flatter surface.

SPS OVERLAY BENEFITS

- Cost-Effective: SPS is less expensive to build and maintain. It requires less welding, labor and material generating reduced maintenance costs.

- Time Saving: Installation causes less disruption and takes less time than a traditional repair, Countless operational hours can be saved by performing steel repairs with Sandwich Plate System (SPS) instead of traditional crop and renew methods. No shutdown period required.

- Enhanced Safety: Approved globally by all major classification societies.

- Improved Performance: Compared to traditional and conventional “crop and replace” methods, SPS is a faster and simpler process because of its reduced weights among other things. But equally strong. Besides the reduction of corrosion and fatigue allow to Increase service life of a structure.

- Environment friendly: With a lower carbon footprint and a 100% renewable feature, SPS overlay is helping to protect the environment.

CERTIFICATIONS

- CTS is one of the only offshore and marine operators worldwide licensed to install SPS.