3D Liner Scanning and Engineering Services

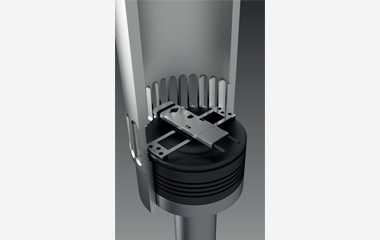

We utilise our proprietary machine that can be easily deployed from the liner scavenger ports to inspect and analyse the liner.

The inspection will provide:

- Liner diameters, wear rates and ovality data.

- Liner issues such as scuffing, clover leafing and any high corrosive wear.

The main concerns for tankers are:

- Immobilisation of the main engine.

- Very short and uncertain port stays.

Our Method

No immobilisation of the main engine is required and no engine mounting needs to be removed. Additionally, our sophisticated technology only takes 20 minutes to scan per liner. Saving you time and accommodating more schedules.

Upon setting up the machine it intelligently self-calibrates and records the required data. Working on the principle of measure by laser, it provides 3D liner wear analysis. From this, the data is then decrypted, giving our experienced technicians the ability to analyse the information and give advice to the client on the available options thereon.

Our Specialities

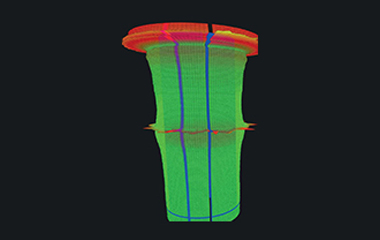

Our 3D laser scan inspections only last 20 minutes per liner and yet provide one of the most comprehensive and detailed reports currently on the market. By engaging laser technology, your report will derive from millions of micro points that will constitute a final 3D scan whereby all the points are systematically arranged in virtual space to give us a visual representation of the current state of the vessel’s liner. Importantly, this is all done without the need of immobilisation or removal of any engine mounting, making this entire process much quicker and simpler than traditional methods.

What the scan provides:

- Maximum liner diameter (machine scans around 290 readings of the liner at various points while continuously rotating).

- Average wear rate and determines the remaining life hours of the liner.

- Interpretation of the ovality curves of the liner.

- The tabulated data is used to graph the wear profile along the full depth of the liner.

- The data is interpreted to point out concern/issues of cloverleafing, adhesive wear and corrosive wear.

Finally, CTS also utilises a camera that will capture the liner and cylinder head so that the images can be co-related to the graphical data to show any issues/failures using our proprietary technology which we developed in the last 12 years.

ADVANTAGES

| CTS OFFSHORE AND MARINE LIMITED | COMPETITOR |

|---|---|

| 3D scanning that does not require contact with the liner | Uses micrometer technology that does require contact with the liner |

| Liner inspection lasts only 20 minutes, saving you time | Takes around 1/1.5 hours per liner |

| Very accurate results as it involves Laser technology | Accuracy is the dependent on the micrometer principle |

| No immobilisation required | The engine must be immobilised and permission obtained from port authorities |

| No engine mounting need to be removed | Engine mounting needs to be removed |

At the forefront

Our carefully selected and factory trained team are chosen due to their training and on-hand experience. Making our specialist technicians a real asset in conducting a confident scan and accurately decrypting the scan results in order to detail the client on the state of the liner in a clear and easy to understand manner so that a careful decision can be made. Our technicians will also be able to suggest best solutions to the situation and assist you in moving forward.