Project Description

CLIENT | M3NERGY

VESSEL | Perintis

DATE | August 2010

LOCATION | Malaysia

Project Brief

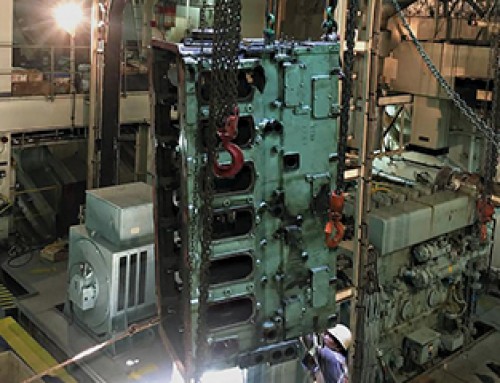

The FPSO Perintis is stationed 155 miles offshore Malaysia in the MASA field. It produces up to 55,000 barrels per day of crude oil and gas. After successfully completing a stringent selection procedure and becoming the preferred vendors for the job, the formidable challenge posed to CTS was to carry out extensive steel replacement on five water ballast tanks to meet ABS specifications.

The client required a turnkey solution, so CTS was in charge of logistics, project management, budget control, operations and process compliance. To add to those challenges, FPSO Perintis presented a hostile environment fraught with dangers from the weather and the cargo.

Scope of Work

Firstly, safety was our primary concern when executing specialized steel repairs with such hazardous cargo on board. Secondly, with the value and volume of crude oil and gas, the other main priority was limiting downtime for the client. CTS’s welding specialists completed the job using methods that allowed work to safely continue simultaneous to normal operation.

Results

CTS completed the steelwork safely, within budget, without disruption to the vessel’s operation and weeks ahead of schedule. Having CTS Offshore and Marine design and manage the project protected the value of the asset and maximized the client’s earning days.

Client Feedback

“The CTS team ensured the Perintis remained fully operational while the steelwork was done and completed the project weeks ahead of schedule”