Project Description

CLIENT | Ship Owners

VESSEL | Refer Container Vessel – 5 Sister Ships

DATE | December 2016

LOCATION | Poland, Germany

Project Brief

CTS was invited by the owners to inspect and execute the retrofit on a Turnkey basis for a series of 5 container vessels to increase the refer carrying capacity by 20 percent. The client required ship specific adaptation and fabrication/installation of the new ducts & fans based on CFD calculations.

The CTS team was deployed to the vessel to execute following-

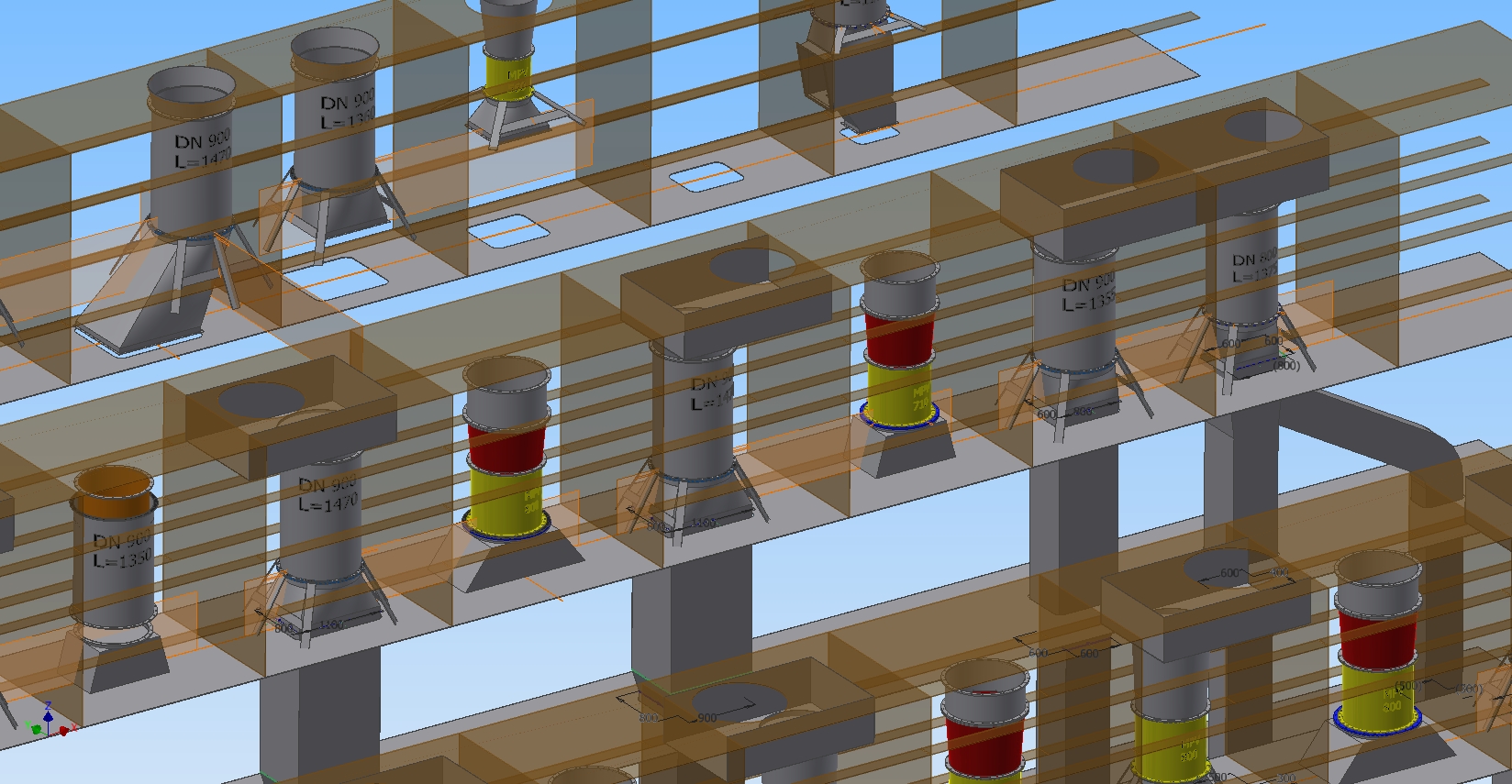

- Inspect and produce ship specific execution duct designs and plans.

- Arrangement of steel team with material and equipment to make openings for duct insertion and required strengthening of the deck.

- Exhaust air flow analysis and drawings for new mushroom vents.

- Fabrication and installation of ducts.

- Execute on plans and drawings for new fan installation and old fan exchange.

- Testing and commissioning of the system.

All works were inspected and approved by classification society.

Scope of Work

CTS divided its team into-

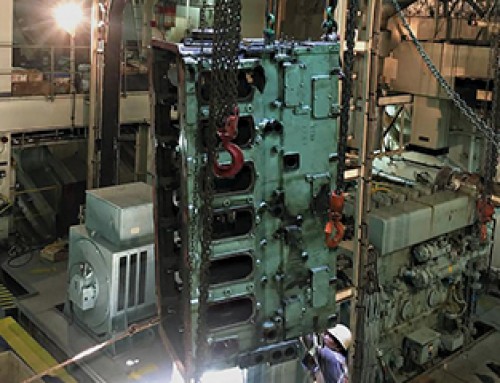

- Steel Works

- Ducting Installation

Both teams were led by a team designer/supervisor who developed ship specific drawings and directed the teams. All works were carried out safely and with zero accidents.

Project Gallery

Results

CTS adhered to timelines and varying requirements of the project to achieve the desired result. In view of the complexity of the project clients recognised CTS capabilities and put us in charge to lead other contractors to achieve deadlines, often working in conjunction and providing practical solutions.

Client Feedback

CTS’ professional approach and ability to cope with the varying demands of the project was appreciated by the managers and owners.